Airbus

Commercial

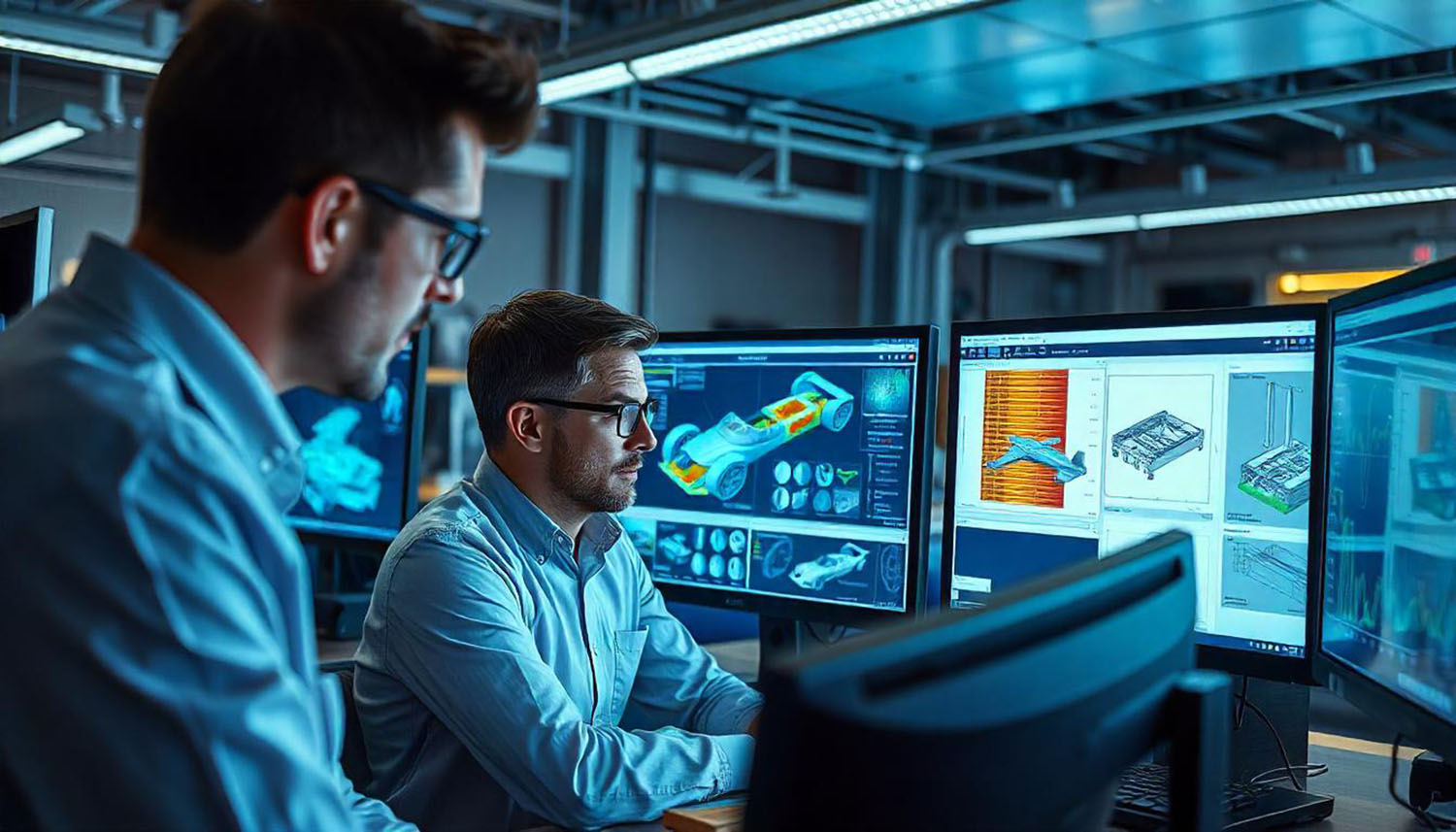

Artemis Composites’ technology was selected as part of a development programme led by Airbus to lightweight future aircraft. The goal was to meet the requirements for future single aisle aircraft: a reliable, fully automated high-rate process, and reduced cost and impact, including reduction of scrap and non-conformance and elimination of consumables.

A generic aerostructure component was selected with Airbus Atlantic. Screening of mechanical performance was completed to aerospace standards and requirements.

The project was supported by the CORAC (Conseil pour la Recherche Aéronautique Civile)